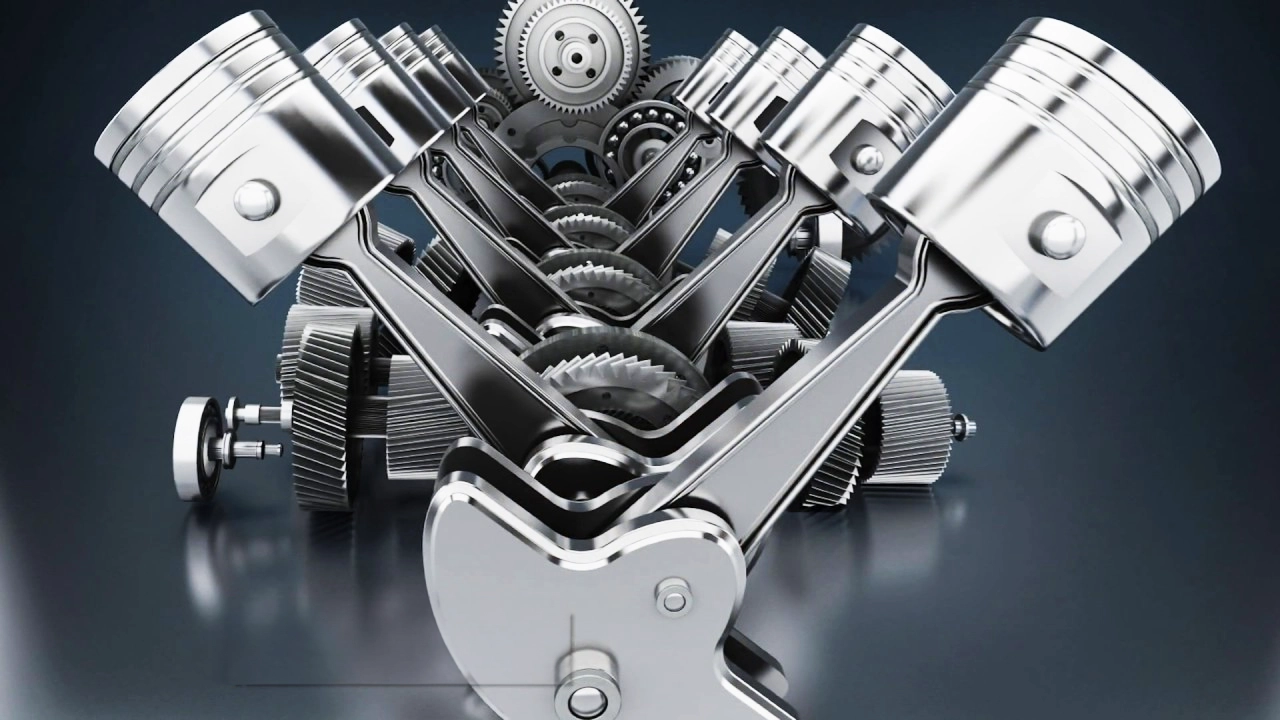

Rebuilding a V8 engine is a project that entails bringing the engine’s internal parts back to like-new condition. This process is often necessary to address issues such as wear and tear, low compression, oil consumption, and loss of power. Whether you’re a car enthusiast seeking to revive a classic vehicle or a pragmatic owner looking to extend the lifespan of your daily driver, understanding the cost and process involved in rebuilding a V8 engine is essential. We’ll examine the several aspects that affect the price of rebuilding a V8 engine in this extensive guide, along with a thorough description of the procedure.

Factors Affecting the Cost of Rebuilding a V8 Engine:

Engine Condition:

The initial cost of rebuilding a V8 engine depends on its current condition. Engines that have been well-maintained and have minimal wear and tear may require fewer replacement parts, resulting in lower overall costs. On the other hand, engines that are severely damaged or have significant wear may necessitate extensive repairs and part replacements, driving up expenses.

Parts Quality:

The replacement parts used during rebuilding can significantly impact the overall cost. Opting for OEM (Original Equipment Manufacturer) parts ensures compatibility and reliability but typically comes at a higher price. Alternatively, aftermarket parts may offer cost savings, but their quality and longevity can vary.

Labor Costs:

Labor expenses constitute a substantial portion of the total cost of rebuilding a V8 engine. The complexity of the engine, as well as the skill level and hourly rate of the mechanic or shop, influence labor costs

Machine Work:

When rebuilding an engine, machining services are frequently required to get the parts back to factory standards. Services such as cylinder boring, honing, crankshaft grinding, and valve seat machining ensure optimal performance and reliability but add to the overall cost. The chosen level of restoration and the engine’s condition determine how much machining is needed. Investing in quality machining services is crucial for achieving a durable and high-performing rebuilt engine.

Performance Upgrades:

Some enthusiasts may opt to incorporate performance upgrades during the engine rebuilding process. Upgrades such as high-performance camshafts, pistons, intake manifolds, and exhaust systems can enhance power, torque, and overall engine efficiency. However, these upgrades entail additional costs beyond rebuilding. It’s essential to weigh the benefits of performance upgrades against their associated costs and determine whether they align with your goals and budget for the rebuild.

Process Overview of Rebuilding a V8 Engine:

First, an inspection is performed on the engine to determine its state and pinpoint any areas that need repair. It entails removing various pieces to inspect the internal components and visually analyzing the engine’s exterior bearings, cylinder heads, pistons, crankshafts, and camshafts for deterioration or deformation. Once the inspection is complete, the engine is disassembled, with each component carefully removed and labeled for reference during reassembly. After disassembly, all engine components undergo a rigorous cleaning process to remove dirt, grime, carbon deposits, and other contaminants.

- Nearly 30% of UK Drivers Believe Car Tax Should Be Based on Mileage — Survey

- Why Planes and Boats Escaped the Luxury Tax But Cars Didn’t

- Australia’s Headlight Confusion: Authorities Warn Drivers After Viral $250 Headlight Rule Goes Wild Online

- 2025 Hyundai Venue Facelift Launched in India – Full Details, Variants, and Price

- Royal Enfield Bullet 650 Unveiled at EICMA 2025: A Classic Legend Returns

It is essential for ensuring the proper function and longevity of the rebuilt engine. Various cleaning methods may be employed, including chemical cleaning, hot tank cleaning, ultrasonic cleaning, and abrasive blasting. Each component is thoroughly cleaned and inspected to ensure the required standards for reassembly. Critical engine components such as the cylinder block, cylinder heads, crankshaft, and connecting rods may require machining to rectify dimensional deviations and surface imperfections. Precision machining is essential for restoring these components to their original specifications and ensuring proper fitment and function.

The extent of machining required depends on the condition of the engine and the specific requirements of the rebuild. It may include pistons, rings, bearings, gaskets, seals, valves, valve springs, and timing components. It’s essential to use high-quality replacement parts that meet or exceed OEM specifications to ensure durability and reliability. Each component is carefully installed and torqued to the manufacturer’s specifications to ensure proper fitment and function. Attention to detail is crucial during the assembly process to prevent errors or issues that could affect the performance or reliability of the rebuilt engine.

Proper lubrication and sealing of components are also essential to premature wear and ensure optimal performance. Once assembled, the rebuilt engine undergoes rigorous testing to verify functionality, compression, and oil pressure. It may involve cranking the engine to check for proper compression, performing a leak-down test to assess the integrity of the seals and gaskets, and running the engine on a test stand or dyno to evaluate performance.

How Much Does It Cost To Rebuild A V8 Engine

A typical v8 engine rebuild may cost between $2,500 and $4,000, including components and labor. If an engine rebuild costs about the same as replacing your engine, you should definitely go with new parts!

Frequently Asked Questions

The fundamental difference between a V6 and a V8 engine is the number of cylinders used for fuel intake. A V6 engine has six cylinders, whereas a V8 has eight. V6 engines typically consume less fuel than V8 engines, while V8 engines produce higher power.Both have their own characteristics and weaknesses.

A V8 engine can generate a maximum torque of 650 ft-lbs. The maximum horsepower is 707. The V12 engines are capable of producing 509 ft-lbs of torque and 850 horsepower. It’s all about personal preference. The V12, with its silky smoothness and grandeur, is for those who seek the ultimate in luxury and performance.

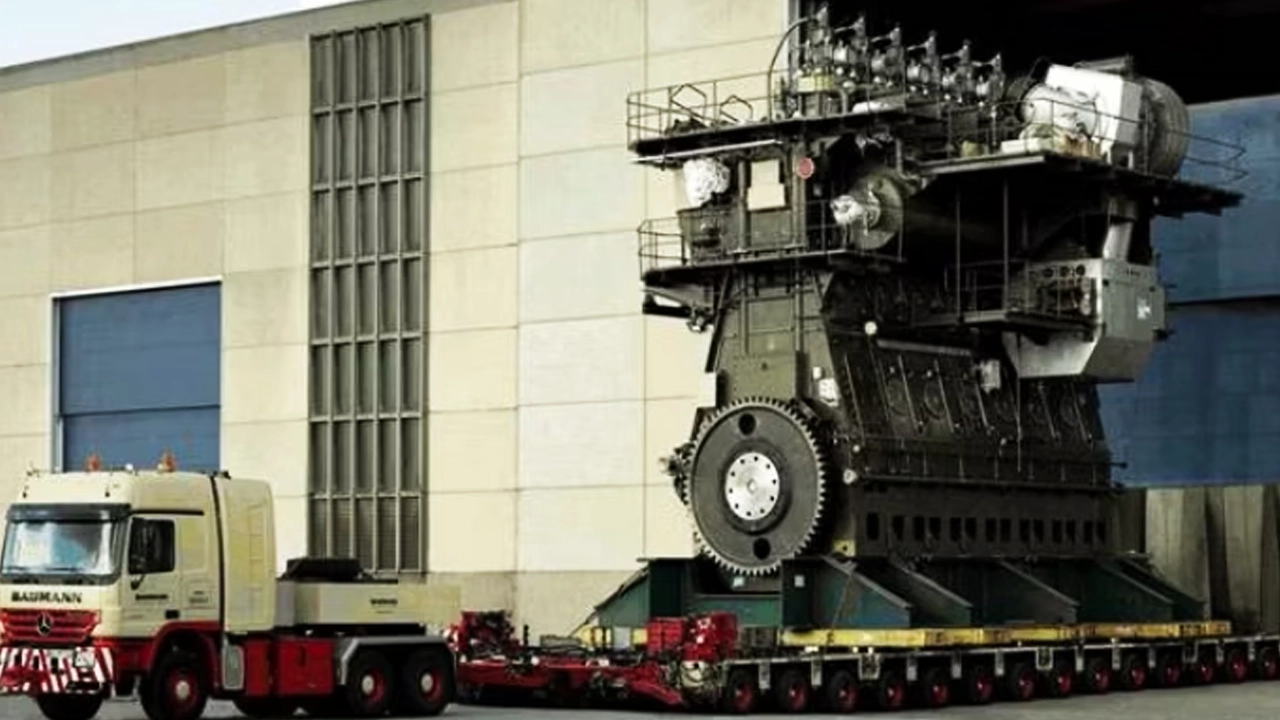

Wärtsilä-Sulzer’s RTA96-C turbocharged two-stroke diesel engine is the world’s largest and most powerful production internal combustion engine. Its maximum power output is 84.42 MW (113,000 horsepower), and its displacement is 1,820 liters (110,195 cubic inches).